Overview:

Injection polyurethane panel is a new type of high-efficiency, energy-saving sandwich panel. The core material is filled by internal foaming and has good thermal insulation properties. It is widely used in the pharmaceutical industry, hospitals, food industry, chemical industry etc.

Product Origin:

ChinaShipping Port:

ShanghaiLead Time:

25

Introduction detail:

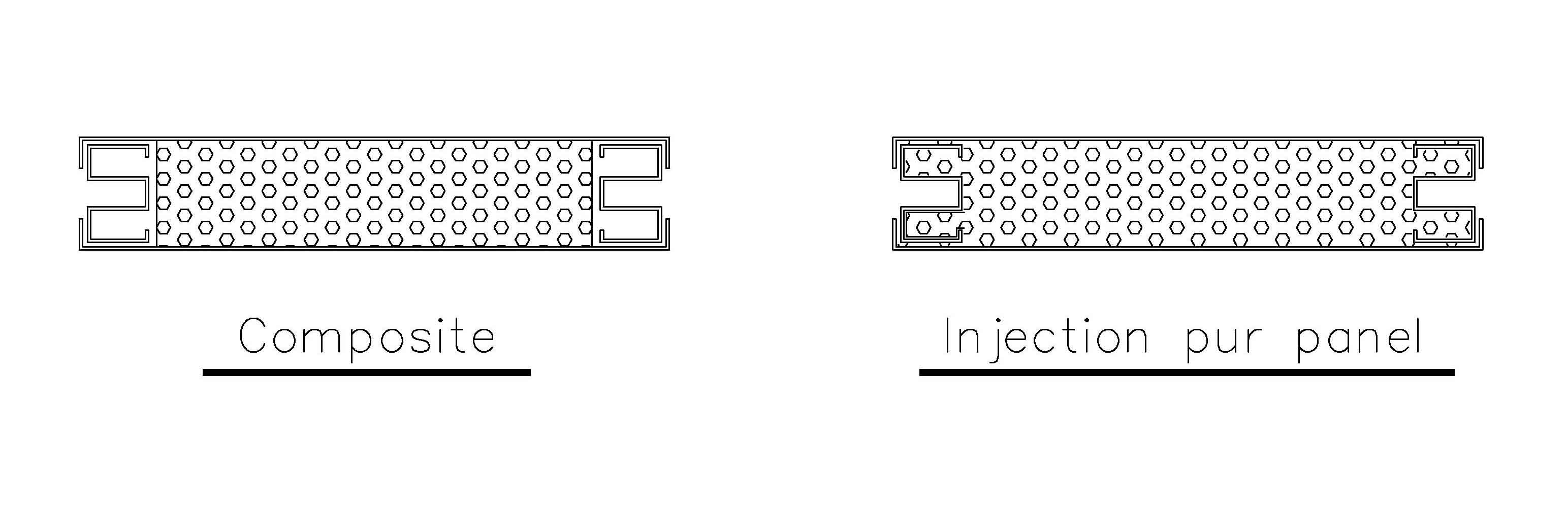

The sandwich material of the injection polyurethane panel is divided into PUR and PIR. The structure of the two panels is different. The frame of the injected PUR panel can be aluminum frame or iron frame, The connection between the two panels is connected by a central aluminum. The injection PIR panel has no frame, and all the production processes are automatic and continuous.The two types of injection polyurethane panel have different fire protection ratings, the combustion performance of PUR is B2, and the combustion performance of PIR is B1 grade. The external material of the injection polyurethane panel is 0.5 mm-0.8 mm coated galvanized steel panel. The thicker the thickness, the higher the flatness.

Detail picture:

Products specification

Heat transfer system

0.018~0.024w/(m.k)

Usage

Central air conditioning, chemical tank and other fields

Colour

RAL 9002/9010, Customized

Unique convex groove structure, good airtightness

Fire rating

PUR B2 PIR B1