Overview:

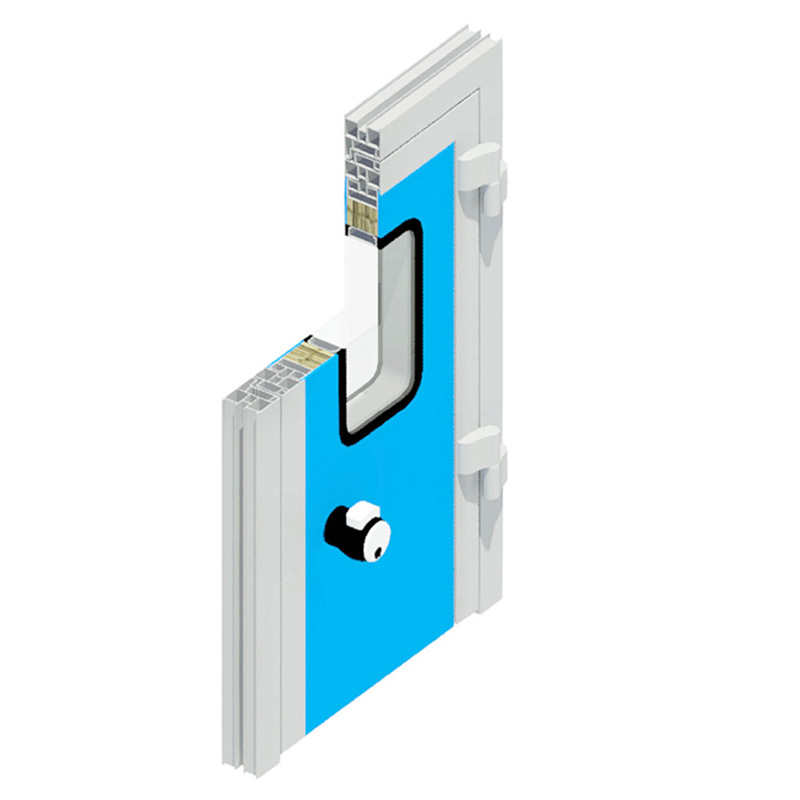

Clean room HPL door consists of a door panel made of HPL sandwich panels and an aluminum frame. Because HPL board has the characteristics of corrosion resistance, impact resistance, high temperature resistance and low temperature resistance, it is mainly used in pharmaceutical industry factories and chemical industry factories.

Product Origin:

ChinaShipping Port:

ShanghaiLead Time:

25

Introduction detail:

Clean room HPL door is made of HPL material, which is made up of aluminum door frame or steel door frame. The door plate is made up of double-layer HPL plate and sandwich material. It has good appearance and good appearance. Also has a bit of all HPL boards, corrosion resistance, high temperature resistance and more. Clean room HPL door is commonly used in pharmaceutical factories, food factories, chemical factories, etc.

Detail picture:

Parameter:

|

Name |

HPL door |

|

Color |

Customized |

|

Material |

HPL, Aluminum, PCGI |

|

Size |

900mm*2100mm, 1800mm*2100mm or customized |

|

Frame thickness |

50mm |

|

Door panel thickness |

40mm |

|

Installation |

Partitions |

|

Application |

Cleanroom, Workshop, Factory |

|

Advantage |

Fire proof rate A |

|

Certification |

ISO9001:2008; SGS |

Products advantage:

1. Good flatness;

2. Corrosion resistance;

3. High strength;

4. Easy to installation;

5. Fire proof