The effective face wind speed setting value of the fume hood, the general industry standard is 60-100fpm (0.3-0.6m/s), generally 100pfm (0.5m/s) is accepted as a safe operation standard. As shown in Figure 1, the movement of the operator has almost no effect on dust collection when the face wind speed is 80-100 fpm, but there will be disturbance effects when the face wind speed is below 80 fpm. When there is no operator moving, general dust collection below 60 fpm can be achieved.

2. Fast system response timeThe net negative pressure in the room mainly controls the flow of airflow from the outside to the inside and prevents the outside of the room from being contaminated. It is an important indicator of laboratory safety control. The generation of negative pressure means that the room's exhaust air volume or the difference between the supplementary air volume and the supply air volume is equal to the residual air volume of the room. The residual air volume is the amount of air entering the room from the room door, transfer window or other gaps other than the supply air.

When the air flow required for room temperature adjustment and ventilation is greater than the air flow required by the fume hood, the air supply volume of the room increases, which requires the control system to also discharge this part of the "excess" air supply volume to ensure Room negative pressure. The total air exchange rate in the laboratory is determined by the total exhaust air, cooling load and minimum ventilation rate. The minimum ventilation rate is generally 6-10 air changes per hour when occupied. This can be achieved by increasing the opening of the room's comprehensive exhaust valve. This control involves the calculation of the room's total air supply and exhaust, as well as information collection and fan frequency conversion control, which greatly increases the difficulty of system debugging.

4.pressure independence5. Precise control system

If the system exhaust volume control cannot follow the rapid and precise change of the static pressure in the duct, it will cause the fume cupboard flow cannot be accurately controlled, and oscillation will occur (as shown in Figure 5), which will cause the room pressure to become a positive pressure or Increase the requirement for the residual air volume in the room. The instability of the wind speed will cause a lot of balance problems. The fluctuating air supply and exhaust system complicates the air flow balance. It will become more difficult for the automatic control system to realize the automatic adjustment function.

The face wind speed should be accurately controlled within a large air volume control range. When reaching the ideal control value, the control system should ensure that the adjusted over-adjustment and under-adjustment are less than 5% to ensure the dust collection capacity of the fume hood and the safety of the operator.

A complete ventilation and control system ensures the safety of the laboratory, which is also the key to the success or failure of laboratory construction. Therefore, the system design, equipment configuration, etc. must meet the basic requirements mentioned above, but the high-standard, high-quality laboratory is not limited to this, but also solves the problems of temperature, airflow, and noise. Guarantee the lowest energy consumption, the system is stable, easy to control, easy to operate and manage. In short, it is necessary to consider the design in terms of safety, comfort, energy saving, and reliable operation.

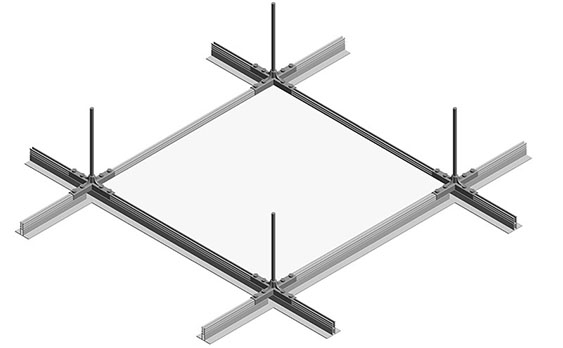

Welcome to inquiry cleanroom false ceiling、clean room accessories for partition wall、cleanroom ceiling grid system and clean room partitioning systems.