The entire process of the air purification project is relatively complicated and requires the cooperation of all aspects to better ensure the work effect. A little carelessness, as long as there is a problem in one of the links, it is possible that all previous efforts will be abandoned, which will have an adverse effect on the production of the enterprise. Let's analyze specifically what matters need to be paid attention to during the construction of the air purification project.

1. In the air purification project, the air purification treatment of all levels of air cleanliness should adopt three-stage filtration of primary, medium and high efficiency air filters. For 100,000-level air purification treatment, sub-high-efficiency air filters can be used instead of high-efficiency air filters.

2. The selection arrangement and installation method of the air filter shall meet the following requirements:

(1) An oil-immersed filter should not be used for the primary air filter.

(2) Medium-efficiency air filters should be centrally installed in the positive pressure section of the purified air conditioning system.

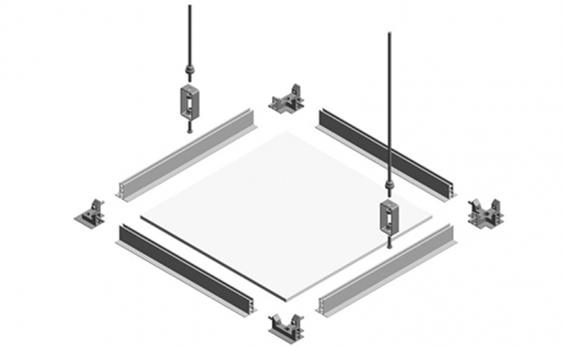

(3) The high-efficiency air filter or sub-high-efficiency air filter should be installed at the end of the purified air conditioning system. The installation method of the high-efficiency air filter should be simple and reliable, and convenient for leak detection and replacement.

(4) Medium efficiency, sub-high efficiency and high efficiency air filters should be selected according to the rated air volume.

(5) High-efficiency air filters with similar resistance and efficiency should be installed in the same purification workshop.

3. When determining a centralized or decentralized clean air conditioning system, comprehensive consideration should be given to the characteristics of the production process and the cleanliness level, area, and location of the clean room air. For those clean rooms with continuous production processes, large areas of clean rooms or purification workshops, centralized locations and strict requirements for noise control and vibration control, it is best to use a centralized clean air conditioning system.

4. If electric heating is required for the purified air conditioning system, tubular electric heaters should be used, and the position should be on the windward side of the high efficiency air filter. Fire safety measures should be provided during use.

5. The blower can be selected according to the total air supply volume and total resistance value of the purified air conditioning system. The resistance of medium and high efficiency air filters should be calculated at twice the initial resistance.

6. In the air purification project, the purification air conditioning system should take preventive measures to prevent the outdoor polluted air from infiltrating into the purification workshop through the fresh air outlet in addition to the direct-flow system and the system with the on-duty fan.

7. When designing the clean air conditioning system, the return air should be used reasonably. In the production process, a large amount of harmful substances will be generated and the local treatment cannot meet the sanitary requirements, or is harmful to other processes, the return air should be avoided.

Welcome to inquiry sliding doors for clean room、clean room partitioning systems、clean room windows and clean room partition wall etc.