In cleanroom construction, lighting systems are often overlooked, yet they are directly linked to cleanliness levels, equipment layout, and long-term operational costs. So how should you choose the right cleanroom lighting? Below, we provide a systematic explanation based on industry expertise.

In a controlled environment, the lighting system not only provides illumination but must also ensure that it does not become a source of contamination. Unlike conventional lighting, cleanroom lighting requires a seamless, fully sealed design with no openings that could allow air or particles to enter the clean zone.

Modern cleanroom lighting has evolved from traditional fluorescent tubes to LED modules and flat-panel LED lights, offering higher reliability and lower energy consumption.

These fixtures are commonly installed in T-grid ceilings alongside HEPA fan filter units. Their smooth, sealed housings sit flush with the ceiling, preventing dust accumulation. Fluorescent lamps were once mainstream, but LED flat panels have become dominant since their cost significantly dropped around 2017.

For ceilings with 100% HEPA coverage, traditional fixtures may take up grid space and disrupt airflow. To address this, teardrop LED fixtures were developed. Their aerodynamic housings minimize airflow interference and mount below the grid. Although they are more expensive and require special mounting systems, they are ideal for high-grade cleanrooms.

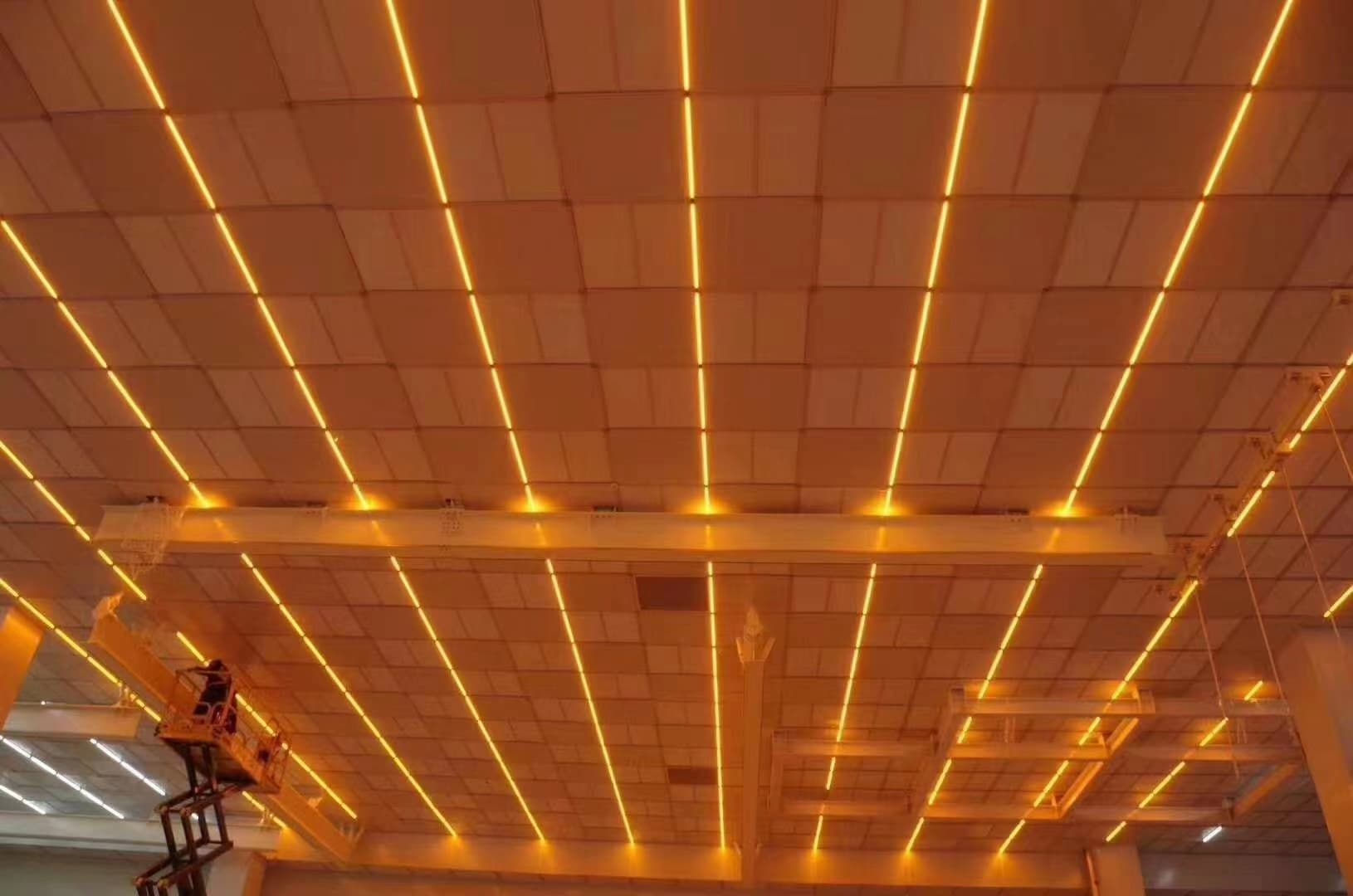

In photolithography or laser-related cleanrooms, fixtures may appear amber or red due to built-in light filters. These filters block specific wavelengths to maintain process stability.

Used in areas containing chemicals or flammable gases, these fixtures feature heavy-duty construction with resistance to corrosion, heat, and harsh environments. They are typically surface-mounted.

For cleanroom projects, companies like wonclean evaluate lighting options based on several key factors:

Choosing cleanroom lighting is not simply selecting a fixture—it requires evaluating cleanliness requirements, process needs, installation constraints, and long-term maintenance. If you are still unsure how to select the most suitable cleanroom lighting solution, feel free to contact wonclean. We will provide professional guidance and integrated solutions tailored to your project needs.